Since 2020, e-commerce has expanded rapidly, and demand continues to grow every year. In a competitive business environment, the final part of the supply chain, when products reach the consumer, is critical. As such, finding ways to improve the last mile – as it is known – can be crucial to a company’s success.

Because the last mile is directly related to the customer experience and getting it wrong can have serious consequences for the company.

SEE ALSO: 4 great reasons to install warehouse protection barriers.

They can be economic, in case products arrive damaged or expired and need to be replaced, or reputational, as dissatisfied consumers are likely to leave negative reviews online and undermine a company’s chances of attracting more customers. Similarly, positive reviews from satisfied customers can be vital in driving sales.

According to a McKinsey report, three in ten consumers are willing to pay for premium shipping. But doing so comes with the expectation of fast, high-quality service.

Therefore, companies that want to attract and retain new customers need to think about how to improve the last mile. This starts with making sure that the distribution center or warehouse setup is fully optimized, so that processing and shipping goods is a fast and efficient process.

If you need someone to help you optimize the installation of your warehouse in Brazil, Mexico or the United States, contact us at.

How to set up your warehouse to improve the last mile

Proper warehouse design is key to efficient operation. Everything must be geared toward a single goal: allowing goods to be processed and shipped quickly, without sacrificing quality of service or safety standards.

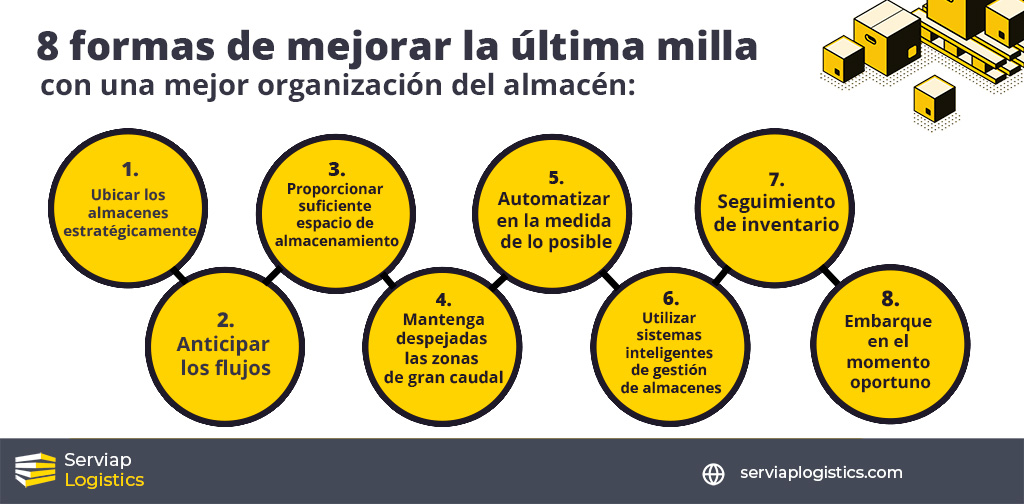

With that in mind, the following eight points highlight ways to improve the last mile and help achieve that goal on a consistent basis.

The points cover a number of aspects, such as the proper selection and use of space, the implementation of the latest solutions for warehouses and distribution centers, and the establishment of appropriate systems.

1) Locate warehouses strategically

If you are in the planning phase of a business or thinking about opening a new location, one way to improve the last mile is to locate warehouses or distribution centers based on where there is the most demand or expected demand.

For customers based nearby, this could drastically reduce lead times, as well as the potential for delivery errors, which can sometimes occur during high-volume long-distance deliveries.

Of course, this is something that needs to be planned in advance and with a long-term vision. Because before you set up a warehouse or distribution center in a particular location, you need to keep in mind where you expect the demand areas to be in the medium term, not immediately.

2) Anticipates flows

The internal flow of goods must be planned prior to the start-up of a facility, with due consideration given to the path of goods and materials from the time they enter to the time they leave a facility.

In many cases, a one-way flow helps to avoid congestion by reducing heavy traffic and thus reducing congestion and the possibility of accidents.

A key tool for signaling flow is the installation of appropriate signage in the warehouse. Another important component can be the placement of markings on the warehouse floor.

3) Provides sufficient storage space

A significant portion of the space in a warehouse or distribution center will be dedicated to storing goods and materials. These areas should be easily accessible and have plenty of room to maneuver.

In many cases, the stored goods will be stored on pallets of different sizes, which must also be stored when not in use.

When planning a warehouse layout, it is essential to know how long goods will be stored and how often they will be picked or moved to ensure optimal use of space.

4) Keep high flow areas clear.

Most warehouses and distribution centers are based on a workflow that involves picking goods from the warehouse that will later be used or shipped and will typically require the creation of designated areas where the picked goods will be placed before being shipped.

Often in a picking area, some preparation is done before goods are shipped, such as wrapping to keep them secure during shipment and consolidating them into shipments for shipping.

In order to improve the last mile in shipments, it is important to keep these areas clear to ship quickly and efficiently.

5) Automate as much as possible.

Today, many warehouses are working with automated processes and AI to streamline workflows and increase the safety of operations. It is the future of logistics.

Warehouse automation includes the use of guided vehicles or autonomous robots, which enable goods to be shipped to their final destination more quickly.

Automation not only makes processes more efficient, but also helps to avoid human error and increase the safety of operations, which by extension contributes to improving the last mile.

6) Uses intelligent warehouse management systems.

Warehouse management systems can make use of artificial intelligence, big data and automation to simplify the complexity of daily operations, track orders and ensure they reach their destination.

Greater use of data analytics enables more efficient operations. An effective system provides reports on the location and number of items and then matches them with customer orders for maximum speed and efficiency and to improve the last mile.

The use of AI also presents great opportunities for time management by predicting how customer demand fluctuates and then optimizing scheduling so that warehouses do not experience bottlenecks or delays.

7) Keeps track of inventory

Optimized, ultra-modern inventory tracking uses advanced technologies such as radio frequency, which allows items to be found and tracked over long distances in the last mile.

This system is very useful, as it facilitates the tracking of all items leaving the warehouse until the time of delivery. Cloud-based inventory tracking allows central nodes to manage multiple warehouses in concert with increasing efficiency.

The right system also allows you to provide timely data. This will alert you to potential shortages at times of high demand, which can help improve the delivery phase of the last leg.

8) Embark at the right time

One option for warehouses is to ship items at non-traditional times to avoid the many inconveniences of rush hour traffic. This usually involves night shifts, but can also include off-peak daytime delivery slots.

There may be restrictions on delivery hours in certain areas, so it may not always be possible to improve last-mile delivery by working at night. However, warehouses can still avoid peak traffic and work around those points.

Another way to improve the last mile is to get goods out of the warehouse earlier, even if they cannot be delivered immediately, as delivery vehicles could save time by avoiding peak traffic hours.

Eight ways to improve the last mile

Serviap Logistics offers warehouse picking services

At Serviap Logística we offer various services for all types of warehouses, such as supply and installation of signage, floor marking, shelving and collision protection.

We also have project management to oversee all aspects of the installation, remodeling or relocation of a warehouse to improve the last mile.

We are present in Mexico, Brazil and the United States, where we work with some of the largest and best-known companies in the world, covering sectors such as automotive, e-commerce and wholesale.

Wherever we work, we are committed to the highest levels of safety and ensure that everyone who works with us has the most up-to-date certifications related to their work.

Contact us to learn more about how we can help you with your warehouse or distribution center configuration to improve the last mile.