Table of Contents

Warehouse floor markings are a critical piece of infrastructure in warehouses and distribution centers, which in most countries are subject to strict regulations.

That means understanding and complying with warehouse floor marking guidelines is usually essential to avoiding compliance issues and legal complications when inspected, as well for maintaining safety and efficiency in the facility.

Depending on the country where you operate, your facility will need to follow local guidelines, which are often similar between different countries, but also tend to include some important differences and partiocularities. Having a thourough understanding of the norms you must work with is therefore important.

For that reason, many managers choose to work with seasoned providers, who have expert knowledge of the warehouse floor marking guidelines applicable in the jursidiction where they work, and can therefore guarantee that anything installed in your space will be full compliant.

Contact us if you are looking for a partner to install warehouse floor marking in Brazil, Mexico, or the United States.

What are warehouse floor markings?

Warehouse floor marking are used in logistics and distribution centers to separate different areas, indicate transit corridors, and overall to enhance safety, efficiency, and organization. Warehouse floor marking guidelines will vary based on the likes of colour usage and the dimensions of the lines installed.

Common floor markings include aisle markings, loading dock markings, safety zones, hazardous material zones, storage area markings, picking and packing zones, and crossing points. Warehouse floor marking guidelines dictate the parameters within which such markings should be placed, in order to standardize

Floor markings obviously have to be durable, and tend to be either painted or applied with specialist paint. Which type suits you will depend on how long they need to last, how soon or often markings will change and your budget for installing them.

Taped floor markings

Tape markings are widely used in warehouses worldwide. The use of high-visibility tape helps clearly demarcate aisles, hazardous zones, and pedestrian walkways. As well as different colored tape, other types also exist which may be needed, such as reflective tape for additional visibility, or freezer tape, which is made specifically for cold storage warehouses.

The advantages of using tape include its cost-effectiveness compared to painted lines, the speed with which areas with taped markings can be used — which is almost immediately after laying it — and the versatility of taped floor marking, which can be easily removed to accomodate workflow modifications.

However, there can still be some drawbacks to using tape, which is less longlasting than paint, and therefore may require replacement sooner. Additionally, tape may be harder to keep as clean as paint, although contracting periodic industrial warehouse cleaning services should help to maintain it.

Epoxy paint lining

Epoxy paint floor markings are an extremely durable option suited for use on lines that are intended to remain for the longterm. The resilience of this specialist paint means it can withstand heavy and regular traffic without degrading.

Epoxy paint floor markings are also easy to keep clean, while in the event of wear and tear, they can simply be touched up in order to be restored to their original standard.

This type of floor marking obviously comes at a higher cost than tape, however that initial investment will be offset by the fact it should last significantly longer. Laying it will also obviously require areas to be out of use while it dries, so it is generally adviseable to have it installed during warehouse setup.

Combing tape and paint

Installing floor markings doesn’t have to be a straight choice between tape and paint, because you may find that the most suitable approach is to combine them. For markings that you know are going to be needed longterm, painting can be ideal. While for any that are likely to be subject to periodic change according to the flow of work, tape can be used.

That will also represent a middle ground in terms of budget, in case that is a facotr in your decision making. If a combination of tape and paint is something you would like to consider, it is obviously important to hire a provider that is experienced in laying both.

Because while many providers will offer both services, some may specialize or be most experienced with one or the other method.

Warehouse floor marking guidelines in Brazil, Mexico, and the United States

Warehouse floor marking guidelines and regulations vary from country to country, so if you are expanding a logistics business into a new jurisdiction, you will need to guarantee compliance with local standards.

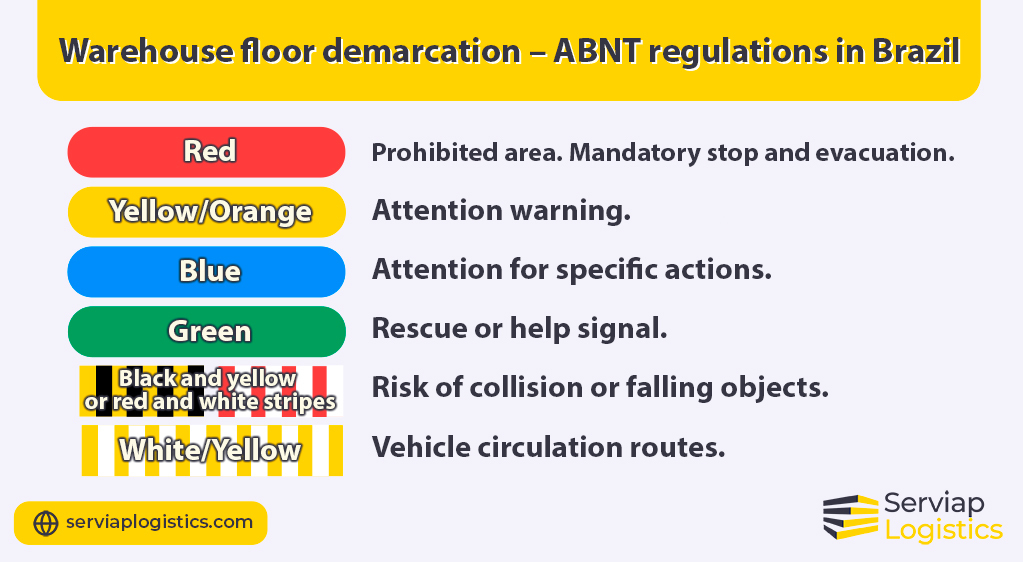

Warehouse floor demarcation in Brazil must comply with rules set out by the National Organization of Industrial Standardization (ABNT). Warehouse floor marking guidelines must adhere to NR 26 standards, which outline specific guidelines for safety colors and signage.

These regulations are designed to create a standardized approach to safety markings, ensuring that all warehouses in Brazil maintain a consistent and recognizable system.

In Mexico, the Federal Law on Metrology and Standardization (pdf) is a key set of regulations for the warehousing industry. Safety regulations are outlined in NOM-001-STPS and NOM-026-STPS, which detail the requirements for safety signs and markings in workplaces.

The norms are applicable nationwide and show the obligations of employers and personnel, among other points. Adhering to these regulations not only ensures compliance but also contributes to a safer environment for employees.

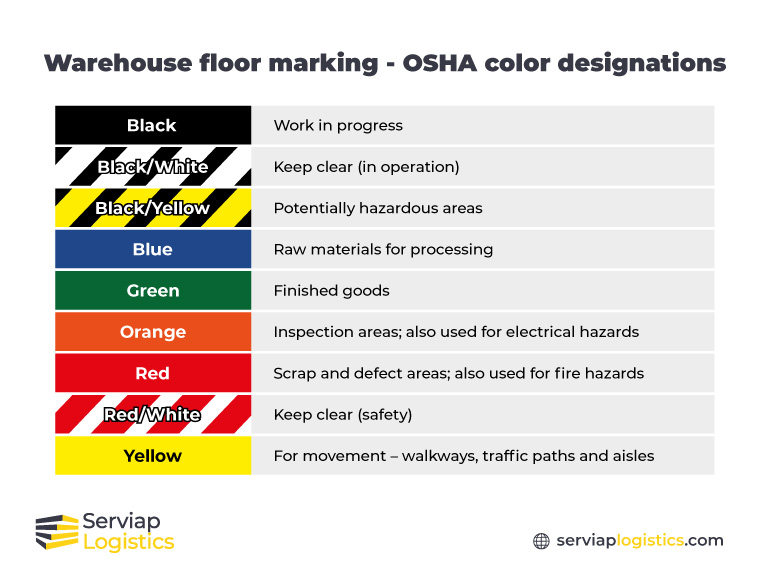

Meanwhile, in the United States, the Occupational Safety and Health Administration (OSHA) plays a pivotal role in setting workplace safety standards, with OSHA guidelines often serving as a general standard in some other countries, as well.

Warehouse floor marking guidelines are particularly addressed in 29 CFR 1910.144, which offers comprehensive guidance on the use of colors for safety markings. OSHA’s color-coded system aids in quickly conveying information about potential hazards, helping to prevent accidents and injuries.

Ensuring proper floor marking installation

Skilled installers can bring an experienced eye to help with your setup and guarantee you adhere to all relevant warehouse floor marking guidelines. They can also offer consultation on your floor marking plan and suggest improvements or modifications to better suit your needs.

An seasoned provider will have the expertise to use specialist equipment and avoid any mishaps during installation, and will also be able to assist you with future modifications and inspections.

Often a provider of warehouse floor marking will also offer additional related services, which could be particularly useful if you are installing demarcation during a setup, refit or relocation.

Alternatively, even if you only need assistance with installing floor marking, a provider with a broad portfolio of services could later be useful in other ways, so it is ideal to have your future plans in mind when contracting floor marking services.

Serviap Logistics offers warehouse floor marking services

At Serviap Logistics, we provide and install warehouse optimization services in Brazil, Mexico, and the United States. Those include floor marking, which we always install in full compliance with local warehouse floor marking guidelines and regulations.

We also provide and install racking, collision protection, and signage, as well as suppling labels and offering industrial cleaning services, while our warehouse project management services include a comprehensive package of services to help you with a setup, refit, or relocation from start to finish.

Our commitment to excellence and ability to hit tight deadlines is well-known among our clients, who include some of the biggest and best-known companies in the world, covering a wide range of sectors, including agriculture, automobiles, e-commerce, and wholesale.

Contact us today to find out more about how we can assist you.