Table of Contents

Warehouse floor marking is essential for dividing areas within a facility, often accomplished through the use of floor marking tape. Combined with appropriate signage, it ensures the safety of both individuals and products in the workplace. These marks serve as visual cues for organizing and utilizing the space effectively.

They fulfill several key functions within the warehouse, including demarcating and identifying different work areas, guiding traffic zones, reinforcing safety signs and systems, enhancing operational efficiency, and providing clearer delineation of restricted or prohibited areas.

By employing warehouse floor marking, the facility promotes order, safety, and improved overall functionality. But, to create the best marking system for your space, it is wise to know more about the different types and usages of floor marking tape, as well as alternative options.

If you are in Brazil, Mexico, or the United States, and need detailed information on floor marking, contact us today.

Using floor marking tape for fast efficiency

The most used type of warehouse floor marking is tape. It involves swiftly applying adhesive to the floor, and its flexibility allows for relatively easy removal and reapplication. They usually are more cost-effective compared to other methods, and faster to apply.

However, there can still be some drawbacks to using tape. If application is not well planned and handled, it becomes less durable, especially in areas with heavy foot traffic. Additionally, the tape can be challenging to clean thoroughly, so it’s important to invest in proper industrial warehouse cleaning.

It is also crucial to ensure the maintenance of floor marking, because even highly durable materials can become detached, damaged or fade without adequate care. By prioritizing maintenance, the frequency of repairs or replacements can be minimized in the short to medium term.

Don’t forget to educate employees about the correct care of these markings. There are general recommendations to follow, such as avoiding driving machinery wheels over the lines, utilizing mats to keep footwear clean, removing objects or debris that might obstruct the surfaces, and preventing the spillage of corrosive substances.

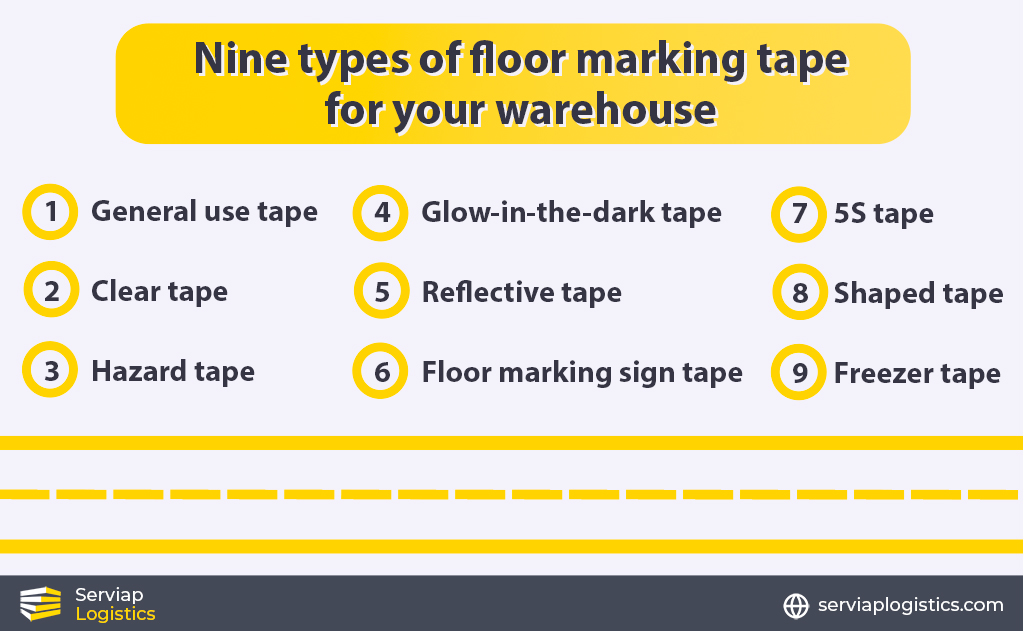

Types and uses of floor marking tape

Floor marking efficiency can be improved when you know which type of tape can be used in different areas of a warehouse. Here are nine common options:

1) General use tape

The general tape is a low-cost option for color coding, bundling, and safety marking applications. They can be used for most standard purposes in transit areas, as well as decorating or offering simpler temporary protection of equipment. They can be found in a wide variety of colors, costs, and durability.

2) Clear tape

Clear tapes are a versatile option for applications where no visual marks are necessary. These are also commonly double-sided, and can be used to stick two surfaces together, as well as mount small objects onto walls or machinery.

3) Hazard tape

For safety measures, hazard tapes are easy to install, and come in striped patterns in many colors. They highlight hazards, dangerous areas, and potentially dangerous routes and areas. These tapes should comply with local warehouse safety standards to provide accurate visual instructions and make safe navigation easier.

4) Glow-in-the-dark tape

Photoluminescent tapes can solve specific problems in a warehouse. They keep glowing for many hours after you turn off the lights, so they are useful option for darker areas or even fully dark warehouses as well. The application of this floor marking tape can improve safety in emergency evacuation routes, as lighting may not be functional.

5) Reflective tape

Reflective tapes will easily call people’s attention during the day and night. They are made of materials that create a highly reflective surface. This floor marking tape is a valuable solution for improving visibility in various areas such as storage spaces, loading docks, and aisle ways. It’s very useful for dimly lit but not dark environments.

6) Floor marking sign tape

Adhesive signs can be applied with custom messages, or regular safety markings. Floor marking signs serve a range of purposes, including indicating traffic patterns, identifying the location of safety items, and creating awareness of specific areas or hazards. This type of tape tends to be much more durable and heavy duty than others.

7) 5S tape

The 5S floor marking tape is a multipurpose option used in many places, even beyond warehouses. Originally from Japan, this is a full system of using tape in logistics. They come in an assortment of colors that can help you implement the 5S floor marking complete guide in your warehouse.

8) Shaped tape

You can buy floor marking tapes that are pre-cut in different figures. They can help with faster applications in more complex routes. Some common options are L-shaped, T-shaped, arrow-shaped, pre-spaced, and cross-shaped floor marking tape. Combining shapes can be perfect for accuracy and customization.

9) Freezer tape

The freezer floor marking tape is especially resistant to lower temperatures. They are perfect for walk-in freezers and cold storage warehouses. These tapes are usually thicker and long-lasting and respond well to freezing temperatures, so you won’t need to defrost an area prior to their application.

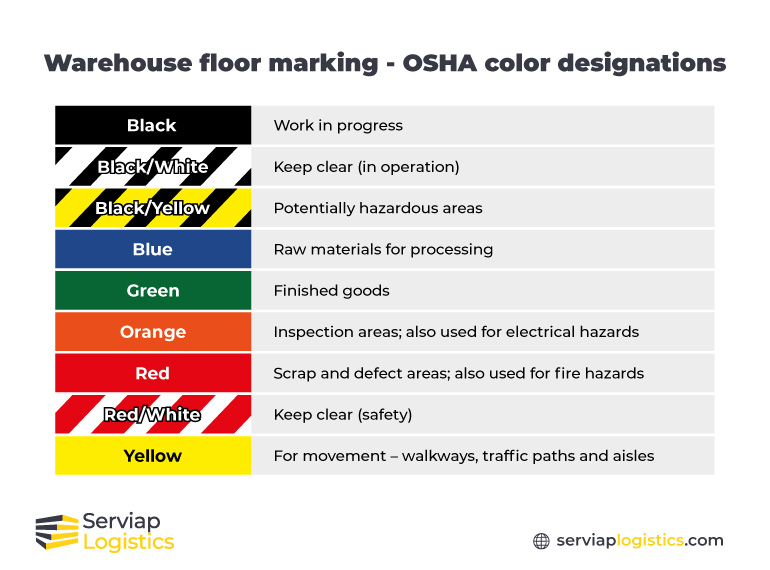

Standards and color considerations

One of the main purposes of the warehouse floor marking tape is to facilitate the safety of operations in as many ways as possible. The colors indicate the nature of activities or potential hazards in a specific space. Hazardous areas often receive additional emphasis through the use of alternating colors. It is imperative for all employees to be familiar with the color code.

Consistency in sizing is also important for applying floor marking tape. According to OSHA recommendations for the US, stripes should have a width ranging from two to six inches, with four inches being the standard for warehouse floor markings. Wherever a warehouse is set, managers should be aware of local regulatory norms for safety and floor marking.

For OSHA, black means work in progress, while black/white denotes areas that need to be kept clear during operation, and black/yellow indicates potentially hazardous zones. Blue represents raw materials for processing, green is assigned to finished goods, and orange is used for inspection areas and electrical hazards.

Then, red is associated with scrap and defect areas, as well as fire hazards, and red/white signifies areas that need to be kept clear for safety. Finally, yellow is one of the most common colors for general areas. It is allocated for movement-related places such as walkways, traffic paths, and aisles.

What are the alternatives to floor marking tape?

There are some factors to consider when choosing the most appropriate option for warehouse floor marking, including the type of flooring, duration, and flexibility. Other variables such as the strength of material and costs might help you in deciding which one is best for each occasion.

Epoxy paint is the most common alternative to floor marking tape. It has great durability and can be more resistant to chemical cleaning or heavy transit in high-traffic areas. However, paint materials are more costly. Furthermore, the floor needs to undergo proper treatment before the paint can be applied.

If you want an even more permanent option, you can also embed warehouse floor markings directly into the surface. This choice is usually made in operations that won’t need much adaptation in the foreseeable future, as it is a long-lasting decision. These marks have a one-time application but require very incisive work for any repair or modification.

Then, a newer option is virtual marking. You can use sign projectors to create light marks on floors, walls, and machines. This approach presents an innovative way of diminishing physical marking materials, providing long-term cost-effectiveness, and a very modern visual disposition. Nonetheless, the initial investment is still much higher, as you need to acquire the equipment.

Serviap offers efficient floor marking tape services

At Serviap Logistics, we provide plenty of warehouse setup services in Brazil, Mexico, and the United States, overseeing operations of remodeling, installation or relocation of warehouses from start to finish.

We started out in Mexico, and our business has since grown internationally. Our goal is to maintain excellence and provide personalized high quality services to all of our customers, ensuring compliance with local regulations.

We can help you in planning your floor marking project, in collaboration with many other services we offer, such as racking, labels, signage, legal compliance and collision protection.

Contact us today to know how we can assist you with floor marking tape services and more.